Commercial Roofing

Our commercial roofing solutions safeguard, strengthen, and futureproof buildings.

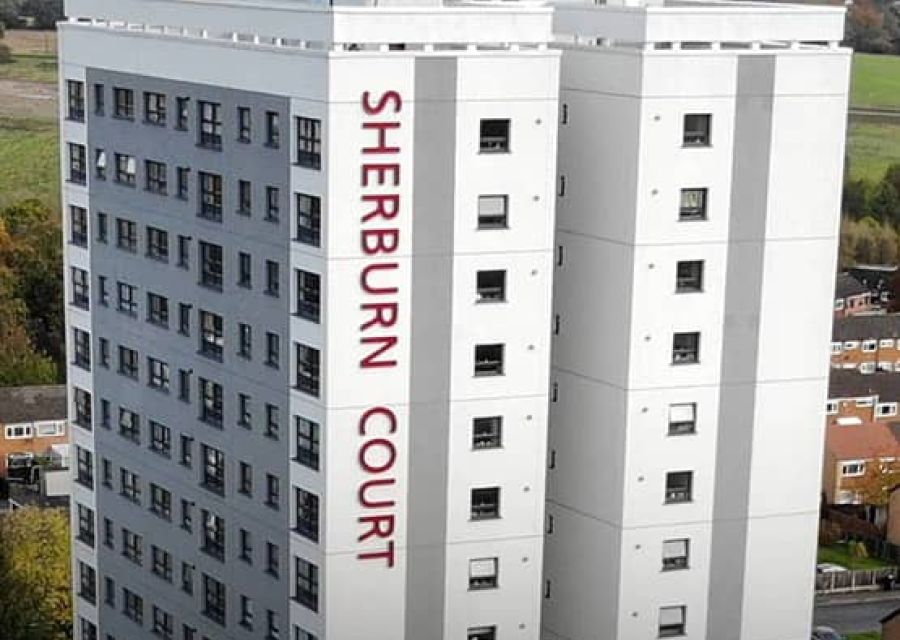

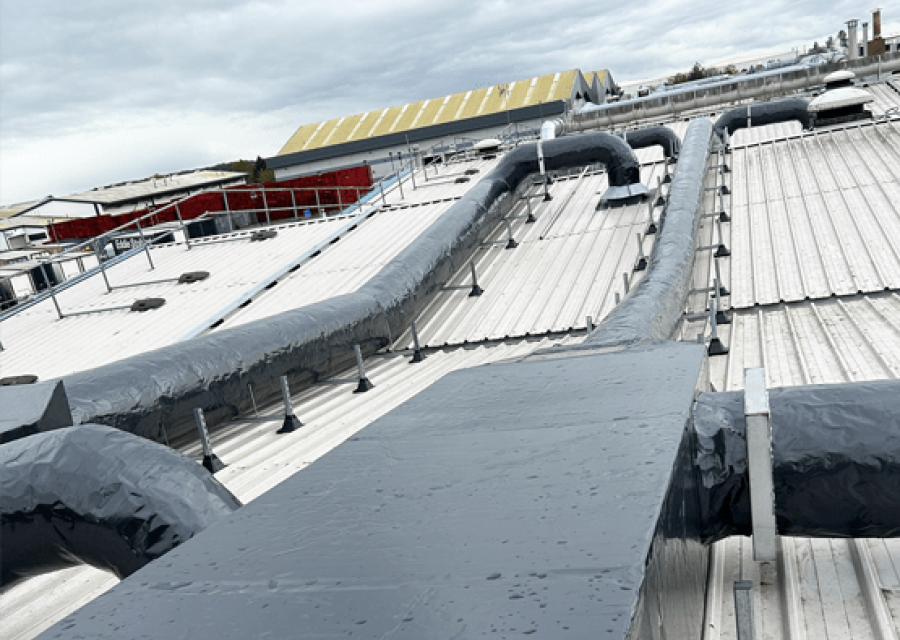

From technical roof surveys to design and installation, including Reinforced Autoclaved Aerated Concrete (RAAC) removal, we deliver systems that enhance safety, energy performance, and long-term value. Whether for hospitals, stadiums, warehouses, or schools, we tailor every solution to meet the needs of complex buildings, ensuring resilience, compliance, and sustainable performance across every roof we deliver.

Explore our roofing solutions below.

Roofing Expertise for Critical Sectors

Our expertise, accredited personnel and sector experience, support clients, including the Ministry of Defense, retail groups, educational and student accommodation buildings, the manufacturing sector, and NHS Trusts. Our approach, management and warranties ensure safety, efficiency, longevity and asset value. Our extensive delivery of roofing solutions spans flat roof installations, roof cladding and overcladding, asbestos roof removal and remediation and RAAC management.

We provide roofing remediation and new build roof solutions, delivering compliance, energy performance, and climate resilience, designed to meet the future needs of complex buildings.

Explore the core areas of our commercial roofing expertise.

Expert-led Roofing Solutions that Stand up to Risk, Regulation and Time.

Our experience, management and extensive project roofing portfolio makes us as a trusted partner for private and public organisations throughout the UK. Our integrated teams combine technical expertise, sector knowledge, and leadership to deliver safe, sustainable, and high-performing roofing solutions. Every project is managed to the highest environmental, safety, and commercial standards, whether upgrading legacy systems or delivering future-ready installations.

MARTIN GAUGHAN

COMMERCIAL DIRECTOR, STARFISH CONSTRUCTION

Our roofing services are built on technical insight and proven methodology. We begin with in-depth assessments using drone surveys, thermographic mapping, and intrusive investigations. These reports uncover risks such as water ingress, thermal loss, material failure, and non-compliance. This investigative approach forms the foundation of our roofing design strategy, ensuring every recommendation is evidence-based and tailored to each asset’s unique requirements. From roof insulation and ventilation to fire-rated materials and solar-ready systems, our sustainable designs support an extensive range of roof requirements, locations and environments. Each system is developed around the building’s purpose, enhancing safety and operational performance. We manage the entire delivery process: survey, design, strip-out, installation, and handover, with safety, quality, and compliance as priorities. Using Procore, our digital project management platform, clients benefit from real-time visibility, transparent reporting, and clear communication across every phase. Open communication is critical in live or occupied environments. We collaborate closely with facilities teams, estate departments, and building users to minimise disruption, ensure accountability, and maintain consistent dialogue. Our delivery approach builds trust and enables successful project execution across complex operational sites.

Roofing Services FAQs

Explore Our Project Profiles

At Starfish Construction, our vast suite of Project Profiles demonstrate our continued and successful delivery of safe, sustainable, and compliant building envelope solutions across the UK. From high-rise residential and complex facade remediation programmes funded by the Building Safety Fund to commercial and industrial roofing projects, each showcases our commitment to quality, transparency, and building performance.